AC vs. DC Drives: Which One Should You Choose?

You must understand the differences between AC and DC drives to make the right choice. The selection of AC and DC drives is crucial. It is especially important when it comes to industrial automation and motor control. Both types of drives offer unique advantages and applications. But the choice depends on your specific requirements. In this blog, we'll delve into AC drives vs. DC drives. It will help you explore their functionality, applications, and advantages. Hence, reading this will give you a clear understanding of which drive is the right fit for your needs.

What Are Drives?

Drives are used to control the speed, torque, and direction of electric motors. They enhance efficiency of the motors. Also, they optimize performance. These are essential components in industries ranging from manufacturing to HVAC systems.

What Is AC Drives?

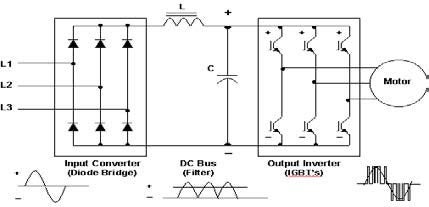

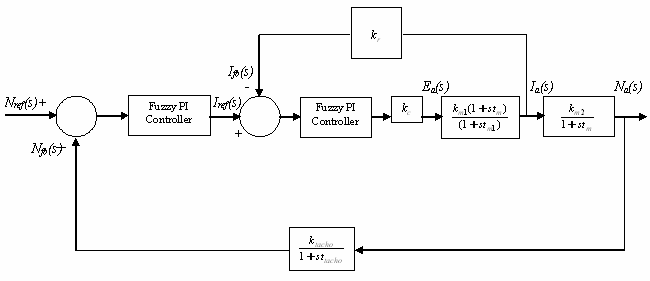

AC drives are also known as variable frequency drives. These devices control the speed of AC motors. They do so by adjusting the frequency and voltage of the electrical power supplied to the motor. This adjustment is crucial in processes where speed and energy efficiency are priorities.

Key Features of AC Drives

-

Energy Efficiency: AC drives reduce power consumption, leading to significant cost savings.

-

Precise Speed Control: They offer excellent control over motor speed. Hence, they are ideal for applications requiring varying speeds.

-

Soft Starting: AC drives minimize mechanical stress during startup. They extend motor life.

-

Regenerative Braking: Energy is fed back into the system during deceleration. This enhances overall efficiency.

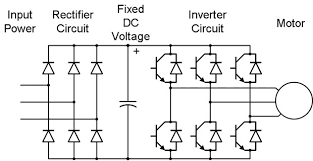

What Is DC Drives?

DC drives control the speed of DC motors. They do so by varying the voltage supplied to the armature or the current to the field winding. These motors have been a staple in industries requiring high torque at low speeds.

Key Features of DC Drives

-

High Starting Torque: Perfect for applications needing significant torque from a standstill.

-

Simple Control: The linear relationship between voltage and speed makes them straightforward to operate.

-

Excellent Speed Regulation: Suitable for tasks requiring consistent speeds under varying loads.

AC Drives vs. DC Drives: A Detailed Comparison

|

Aspect |

AC Drives |

DC Drives |

|

Motor Type |

Works with AC motors (induction and synchronous motors). |

Requires DC motors. |

|

Speed Control |

Adjusts speed via frequency control. |

Controls speed by varying voltage/current. |

|

Efficiency |

Highly energy-efficient with regenerative braking. |

Slightly less efficient due to higher losses. |

|

Maintenance |

Requires less maintenance due to fewer components. |

Needs regular upkeep, especially the brushes. |

|

Applications |

HVAC, conveyors, pumps, and fans. |

Cranes, elevators, and rolling mills. |

|

Cost |

Higher initial investment but cost-effective in the long term. |

Lower upfront cost but higher operational expenses. |

It is essential to understand the difference between AC and DC drives to match their features with your application needs.

What Is a VFD?

A variable frequency drive is an AC drive. It is designed to control the speed of motors. They do so by varying the frequency of the electrical power supplied. A VFD is one of the most versatile and widely used drives.

Advantages of VFD Drives

-

Improved Process Control: VFDs allow precise adjustments to motor speeds. They ensure smooth operation.

-

Energy Savings: They significantly reduce energy usage. This is especially advantageous in systems with fluctuating demand.

-

Reduced Wear and Tear: VFDs extend the life of motors and related components by enabling soft starts and stops.

Applications of AC and DC Drives

Where AC Drives Excel?

-

Pumps and Fans: Variable speed control leads to significant energy savings.

-

Conveyors: Precise speed adjustments ensure seamless material handling.

-

HVAC Systems: VFD drives enhance efficiency and reduce energy costs in heating, ventilation, and cooling systems.

Where DC Drives Shine?

-

Cranes and Hoists: High torque at low speeds is a must.

-

Rolling Mills: The ability to handle high starting loads and maintain speed regulation.

-

Electric Trains: Smooth acceleration and deceleration are critical.

Variable Frequency Drives vs. DC Drives

VFD drives often emerge as the modern solution due to their versatility, efficiency, and wide range of applications. On the other hand, DC drives are reliable. However, they are being gradually replaced in many industries by AC counterparts.

Why AC Drives Are Gaining Popularity?

-

1. Technology Advancements: Innovations in power electronics make AC drives more reliable and user-friendly.

-

2. Wide Availability: AC motors and drives are readily available. Hence, they make replacements and upgrades seamless.

-

3. Lower Maintenance: AC systems require less downtime for repairs with fewer moving parts.

However, DC drives still hold an edge in niche applications requiring exceptional torque and speed control at low speeds.

Considerations When Choosing Between AC and DC Drives

Selecting the right drive depends on several factors:

-

1. Application Requirements: Evaluate the torque, speed, and precision needed.

-

2. Budget: Consider both initial costs and long-term operational expenses.

-

3. Maintenance Capabilities: DC drives require more upkeep, while AC drives are largely maintenance-free.

-

4. Energy Efficiency Goals: For systems with high energy demands, AC drives with VFDs are a cost-effective choice.

What Are VFD Drives: The Modern Standard?

The versatility of VFD drives have revolutionized industries worldwide. They enable seamless speed and torque control. These drives are integral to energy-efficient systems. VFD drives provide the adaptability needed in dynamic environments.

Future of Variable Frequency Drives

The role of VFDs in reducing energy consumption will only grow. This is because sustainability is becoming a global priority. From residential to industrial applications, they are set to remain the gold standard for motor control.

Also Read: Understanding AC Drive VFD Technology: Everything You Need to Know

Conclusion

Choosing between AC and DC drives boils down to understanding your specific application needs and balancing efficiency, cost, and maintenance. While AC drives, particularly VFD drives, are leading the charge in modern automation, DC drives still hold a place in specialized applications.

For a seamless transition to modern drive technology, trust Lauritz Knudsen Electrical & Automation SmartShop. Their expertise and cutting-edge solutions ensure that you find the perfect drive to match your requirements. Whether you need a robust AC drive system or a reliable DC drive, Lauritz Knudsen has you covered. Explore their offerings today and step into the future of efficient motor control.

Comments