Automatic Power Factor Control Panel in Fluctuating and Unbalanced Load Conditions

Power quality is important in the contemporary industrial environment; variations in electrical load and imbalance systems result in inefficiencies and high costs. To overcome these problems, an APFC Panel, an Automatic Power Factor Control Panel, is implemented widely. Originally developed to control the amount of reactive power in a system to enhance power factor, this technology serves a critical purpose in ensuring the costs of power-related functions are kept to a minimum. To understand these factors, let us discuss how automatic power factor controllers work, where you can apply or use them, and the advantages of using this equipment, especially when working in fluctuating and unbalanced load conditions.

Table of Contents

- What is an Automatic Power Factor Controller?

- How Automatic Power Factor Controllers Work?

- Benefits of Automatic Power Factor Correction

- Automatic Power Factor Controller for Industrial Application

- Automatic Power Factor Controller Price

- Types of Automatic Power Factor Compensation

- Applications of APFC Panels in Unbalanced Load Conditions

- Key Features of Automatic Power Factor Control Panels

- Conclusion

What is an Automatic Power Factor Controller?

An automatic power factor controller (APFC) is an electrical device that deals with reactive power to improve the power quality. It measures the system's power factor and regulates any lack of reactive power, maintaining the power factor very close to 1. This device is useful for facilities that experience large insertion and/or unbalanced loads situations because it saves power wastage, minimises stress on the equipment, and results in lower electricity costs.

How Automatic Power Factor Controllers Work?

The power factor is a measure of the efficiency of power usage. Hence, a power factor of 1, unity, means all the power is utilised. Nevertheless, when the power factor is less than one, this situation indicates power factor issues, which require more apparent power to deliver the same real power. This inefficiency may lead to higher energy consumption, bigger ratings of transformers as well as generators, and the generation of more heat.

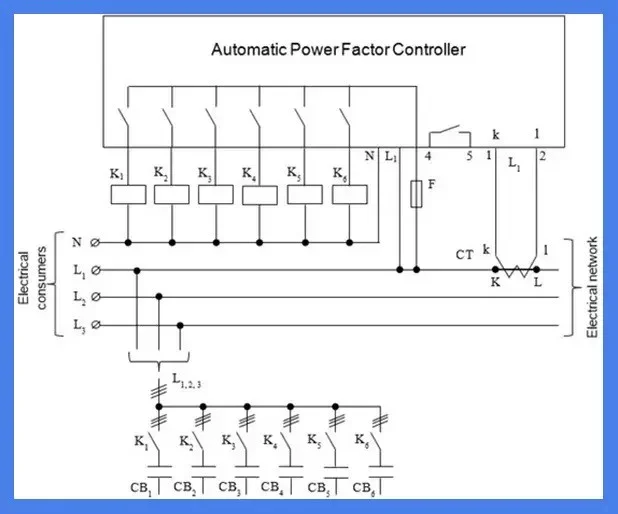

The APC working principle as an automatic power factor controller relies on the continuous control of the actual load condition and the power factor. The controller measures variations in the power factor and control capacitor banks, which either add or subtract reactive power. This adjustment raises the power factor closer to one to maintain a stable power factor that improves the efficiency of the electrical circuit.

The controller takes action if the capacitors in the system make it prone to fluctuating or an imbalanced current load. This affords constant correction of any lagging or leading power factor within the system using a three-phase supply. APFC panels are especially prized for their ability to respond automatically to fluctuations, and load fluctuation, which is very important in industries with transient loads.

Benefits of Automatic Power Factor Correction

Using an automatic power factor correction system brings numerous benefits:

- Cost Savings: Improved power factor reduces costs like penalties on power factor usage, forming the basis for many utilities’ tariff structures.

- Extended Equipment Life: APFC panels ease aggression on transformers and generators, thus increasing the latter’s useful life.

- Reduced Transmission Losses: The overall efficiency of the power supply system increases, and the line losses are reduced, ensuring that more of the generated power gets delivered.

- Eco-Friendly Operations: Less power consumed means less carbon is emitted into the environment, which many industries need to achieve to improve their sustainability.

Automatic Power Factor Controller for Industrial Application

Manufacturing units, data centres, and automotive manufacturing plants subjected to frequent load changes are ideal beneficiaries of an automatic power factor controller for industrial use. They commonly incorporate apparatuses with high actual reactive power, such as motor, compressor, and large lighting load, which may result in varying and /or non-symmetrical loads. In such conditions, using an APFC panel makes power capacity responsive to fluctuations in the load requirements.

Automatic Power Factor Controller Price

The cost of an automatic power factor controller may range from the system's capacity, the kind of brand, and features such as remote monitoring and data analysis. Although the cost of an APFC panel might be on the higher side at the initial level of installation, the amount of energy conserved and the life duration of equipment that an APFC panel provides makes it economical. From Lauritz Knudsen Electrical and Automation, industries benefit from competitively priced APFC panels packed with solid functionality for the best value.

Types of Automatic Power Factor Compensation

Automatic power factor compensation can be achieved through several methods, each tailored to meet specific industry needs:

- Fixed Compensation: Most suitable for load Constance systems where constant capacitors boost the power factor.

- Stepped Compensation: Applied in conditions with moderate variation and where capacitor banks are switched in stages to compensate for reactive power.

- Dynamic Compensation: It is efficient for cases with a highly varying load as capacitors are altered actively in this type.

Applications of APFC Panels in Unbalanced Load Conditions

Unbalanced loads occur when different phases in a three-phase system have unequal loads, causing equipment inefficiencies and potential overheating. This is where automatic power factor controllers excel. They adjust the reactive power across different phases, helping to balance the load distribution and maintain system stability.

Industries where unbalanced loads are common, such as textile manufacturing, metal processing, and chemical plants, greatly benefit from using automatic power factor control panels. These panels prevent energy loss and avoid penalties associated with unbalanced loads by ensuring balanced power distribution.

Key Features of Automatic Power Factor Control Panels

Automatic power factor control panels come with various features that make them suitable for demanding industrial applications:

- Real-Time Monitoring and Control: Ability to detect load and power factor fluctuations as they occur.

- Adaptive Compensation: Static and dynamic compensation of reactive power depends on load variations.

- Fault Detection: Capability to identify the existence of faults in capacitor banks and, consequently, the capacity to make corrections.

- Remote Access: Supervisory controls for telemaintenance that further improve ease of maintenance.

- Automatic Power Factor Controllers: These are some of the most important investments in contemporary industries.

Also Read: Unveiling Power Factor Correction Capacitors: Their Purpose and Importance

Conclusion

To sum it all up, industries that experience volatile and/ or out-of-balance loads should ensure that they purchase an APCP. It enhances power quality and reduces power consumption, enhancing the durability of electrical appliances. Some of the top solution providers include Lauritz Knudsen Electrical and Automation, which makes it possible for industries to gain the best results even when working under hardship. As energy costs skyrocket and organisations make a concerted effort to be more environmentally conscious, APFC panels offer a smart investment for companies who want to increase power quality. Shop for an automatic power factor controller from SmartShop of Lauritz Knudsen Electrical and Automation.

Comments