Earth Fault Protection for Motors: Ensuring Safety and Coordination with Upstream Breakers

Electric motors play a pivotal role in maintaining continuous operations in any industrial setting. They power everything from pumps and compressors to conveyor belts and cooling systems. However, the very nature of electric motors, which operate with high electrical currents, makes them susceptible to earth faults. These unaddressed faults can lead to severe damage to equipment, create hazardous conditions, and even cause fires. This is where earth fault protection becomes indispensable, ensuring the safety of the motors and the personnel working around them. Let's delve into the essentials of earth fault protection for motors, its types, applications, and the importance of coordination with upstream breakers.

Table of Contents

What is Earth Fault Protection?

Earth fault protection is intended to identify unsafe and unwanted connections to the Earth. The current follows the desired or even the literal circuit in normal conditions. However, an alternative path develops when an earth fault occurs, normally leading to high current exploitation. This uncontrolled current might cause/get to the motor's insulation and dematerialize some of it, affecting the speed of the motor and thus reducing its life span.

Importance of Earth Fault Protection for Motors

Here are a few reasons why Earth fault protection is essential:

- Protection of Motor and Equipment: An earth fault, if not detected, may result in a failure of the insulation on the motor, thus bringing about equipment failure or electrical fires.

- Safety of Personnel: Coulomb discovered that earth faults are dangerous to personnel working closely with motors since they enhance the possibility of electrocution. Earth fault protection systems protect against this by interrupting current flow during faults.

- Compliance and Regulatory Requirements: Almost all plants and industries have standard requirements for safety that, in some capacity, require earth fault protection for particular equipment. Such protection systems for motors make the organisation conform to the required legislation.

- Prolonged Motor Lifespan: Fault protection at constant intervals effectively preserves the motor condition and its utilisation and maintenance duration.

Types of Earth Fault Protection for Motors

Several types of earth fault protection methods can be employed for motors. Each type serves a specific purpose and provides varying levels of safety and sensitivity.

- Earth Leakage Protection: Minor fault detection is possible by using earth leakage protection, which is among the most commonly used. This type of protection detects the leakage currents that occur due to insulation failure, corrosion or mechanical wear and tear.

- Residual Current Devices: They are widely applied in the earth fault protection of motors and other important equipment. These instruments measure differences in currents between live and neutral. When an earth fault occurs in a circuit, the RCD picks up the variation quickly and trips the circuit to prevent further risk of electric shock or further damage.

- Earth Fault Protection Relay: The motor earth fault protection scheme cannot be completed without an earth fault protection relay. This relay recognizes any ground fault condition that is likely to occur. The fault current protection relays used on the earth faults can be set for distinct sensitives depending upon the belts' working conditions and the motor's tolerance levels to the specific faults.

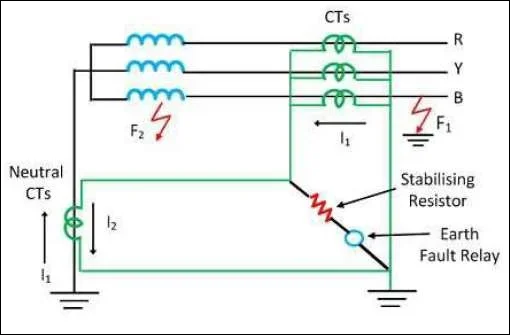

- Zero Sequence Current Transformer: Zero-sequence CT is applied in areas where high sensitivity protection is required. In this arrangement, the CT monitors the currents in the three phases and can detect an earth fault.

- Neutral Grounding Resistor: The NGR controls the fault current by forming a resistive mode for the earth fault current. This protection type minimises the threat level during an earth fault and is normally used in high-resistance grounding systems for motors in particular industries.

Earth Fault Protection Applications for Motors

The earth fault protection application of the motor-driven system can differ from industry to industry. Here are a few practical applications of earth fault protection systems:

- Manufacturing Facilities: In manufacturing, motors must drive heavy and large equipment and conveyor lines. Earth-fault protection is beneficial because faults with the Earth can result in costly downtimes or equipment replacement.

- Oil and Gas: Motors drive pumps and compressors necessary for drilling and production in the oil and gas industry. In this area, any earth fault can cause catastrophes since the environment is highly risky.

- HVAC Systems: Application Motors that drive heating, ventilating and air conditioning equipment realise earth fault protection to guarantee occupants' comfort and safety, especially in large commercial structures.

- Power Generation Plants: Motors are applied in power plants where turbines require operation and also in cooling systems.

- Mining Industry: Motors are widely used in mining processes requiring high safety standards because mining is very harmful. Earth leakage protection and earth fault relays are some factors that prevent and identify possible dangers on mining premises.

Also Read: Everything You Need to Know About EARTH LEAKAGE CIRCUIT BREAKER (ELCB)

Conclusion

Earth fault protection for motors is vital to any industrial facility’s safety system. It safeguards the motor and surrounding equipment and protects personnel from potential hazards. With different types of earth fault protection available, industries can choose the solution that best fits their operational needs and environment. Moreover, by coordinating with upstream breakers, facilities can prevent extensive shutdowns, enhancing safety and productivity.

Reliability is essential when looking for high-quality components to design or upgrade an earth fault protection system. Lauritz Knudsen Electrical and Automation offers an extensive range of advanced electrical products and solutions, including earth fault protection relays and other essential components. Our SmartShop provides access to various options for building a robust protection system for your motors. Choosing Lauritz Knudsen means investing in quality, reliability, and the safety of your facility.

Explore the SmartShop of Lauritz Knudsen Electrical and Automation to find the best solutions for implementing earth fault protection and ensuring continuous, safe operations across all motor applications.

Comments