What is Direct on Line (DOL) Motor Starter? Types & Working Principle

When choosing a motor starter that is usually used to power industrial and commercial machinery, a lot of consideration is required. There are various types of motor starters, but the most preferred one among engineers and technicians is the Direct On Line (DOL) motor starter. It has been a simple and effective system that was applied many years ago, especially in motor control. In this blog, we will give a brief description of what DOL motor starters are, the types of DOL motor starters, where they are useful, and why they are important.

Table of Contents

• What is a DOL Motor Starter?

• Types of DOL Starters Based on Operation and Control

• Types of DOL Starters Based on Power Supply

• Applications of DOL Motor Starters

• DOL Starter Working Principle

• Disadvantages of DOL Starter

What is a DOL Motor Starter?

A direct-on-line (DOL) motor starter is a machine employed to operate and regulate electric motor operations. As the name implies, it links the motor directly to the power supply. This is the reason why it is called direct on line. This method is cheap and efficient; thus, it is used in many applications.

In the case of a Direct On Line motor starter, when the start button is depressed, the supply voltage is directly applied across the motor, which means that from the instance of starting, the motor is supplied full voltage. Such a starter is commonly used in motors whose starting is not very complicated and hence used mostly in small to medium size motors.

Types of DOL Starters Based on Operation and Control

DOL motor starters are of many types because they vary depending on the motor's application and power rating. The most common types of DOL starter include:

• Basic DOL Starter: This is the simplest type of DOL motor starter. They include a contactor, an overload, and the start/stop push button. The basic DOL starter is normally recommended in areas where more complex equipment is not required due to cost issues, among other factors.

• Automated DOL Starter: The use of an automated DOL starter comes with the extra benefits of alarms or lights such as timers or sensors. These improvements make it possible to exercise more authority in the control of motor operations, hence optimal results in complex tasks.

• Remote DOL Starter: Remote DOL starters are basically designed for convenience, which permits starting and operating this motor from a distance. This type is particularly beneficial in scenarios where the motor is hard to access or is placed in a risky area.

Types of DOL Starters Based on Power Supply

3 Phase DOL Motor Starter

Three Phase DOL Motor Starter is used for direct online starting of three-phase induction motors, and it is valued for its simplicity, reliability, and cost-effectiveness.

• Commonly used in factories, workshops, and processing plants where power demand is higher.

• Suitable for motors that need strong starting torque without complex control.

• Works well in continuous-duty applications with stable power supply.

• wiring makes troubleshooting easier for technicians.

• chosen where reliability matters more than smooth starting.

Single Phase DOL Motor Starter

Single Phase DOL Motor Starter is used for direct online starting of single-phase induction motors.

• Mostly found in homes, small shops, and light commercial environments.

• Ideal for pumps, small compressors, and basic machinery.

• Compact size makes installation easier in limited spaces.

• Requires fewer components, reducing overall system complexity.

• Practical choice where advanced motor control is not required.

Applications of DOL Motor Starters

Some common applications of DOL motor starters include:

Pumps

In pump systems, especially in water treatment plants and irrigation setups, reliability matters more than complexity. One major application of DOL starter is where pumps need to start quickly and run continuously without frequent stops. Since these systems usually handle steady loads, a DOL starter offers a simple, cost-effective way to keep pumps running smoothly with minimal maintenance concerns.

Fans and Blowers

Fans and blowers often operate for long hours and require consistent performance rather than controlled speed variation. In this application of DOL starter, the motor reaches full speed instantly, which suits ventilation and HVAC systems well. The simplicity of the starter also reduces wiring complexity, making it a practical choice for air circulation equipment in industrial buildings and commercial spaces.

Compressors

Compressors benefit from the strong starting torque provided by DOL starters. In many industrial environments, compressors are expected to start under load without hesitation. A DOL starter delivers immediate power, allowing the compressor motor to reach operating speed quickly. This straightforward starting method works well where electrical supply strength is stable and operational reliability is a priority.

Conveyors

In manufacturing units, conveyors play a constant role in material movement. DOL starters are commonly used where conveyor loads remain fairly uniform. The motor starts instantly and maintains steady motion throughout operation. This makes DOL starters suitable for simple conveyor systems where advanced speed control is not required and dependable start-stop performance is more important than precision control.

Dol Starter Working Principle

In addition to DOL starter full form, you must also learn about their working principle. The DOL starter working principle is based on a simple idea- start the motor without complication. When power is switched on, the motor is connected directly to the supply through a contactor and an overload relay. There is no gradual buildup of voltage. The motor takes full voltage immediately, draws a high starting current for a short time, and then settles into normal speed. This direct approach is why the system remains widely used.

Power Supply Connection

In a DOL starter setup, the power supply goes straight to the motor terminals. Nothing reduces or controls the voltage during startup. Because of this, the motor responds instantly and develops strong starting torque. This is useful when the load needs a firm push to begin moving. At the same time, the electrical network must be strong enough to handle the sudden current drawn when the motor first starts.

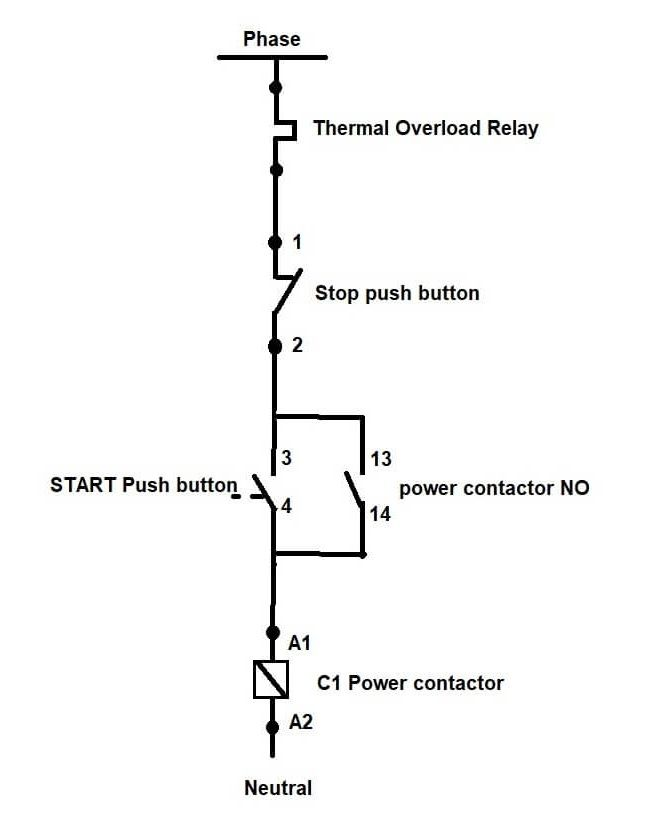

Contactor Operation

The contactor is the working switch inside a Direct On Line DOL starter. When the start button is pressed, the contactor pulls in and completes the circuit between the supply and the motor. Once engaged, it stays closed as long as conditions remain normal. If the stop button is pressed or a fault occurs, the contactor drops out immediately, cutting power and stopping the motor without delay.

Overload Protection

Overload protection exists to guard the motor against long-term stress rather than sudden faults. In a Direct Online Starter, the overload relay constantly watches how much current the motor is drawing. If the motor works harder than it should for too long, the relay trips. This action prevents overheating, insulation damage, and winding failure, helping the motor last longer under everyday operating conditions.

Control Circuit Function

The control circuit handles all the logic behind starting and stopping the motor. It uses low-power components like push buttons, indicator lamps, or PLC inputs to operate the contactor. This means the user never touches high-voltage lines directly. Because of this design, DOL starter use becomes safe and practical, even in busy industrial environments where motors are switched on and off frequently.

Dol Starter Wiring Diagram

A DOL starter wiring diagram shows, in a simple visual way, how electricity moves from the power supply to the motor. It explains where the contactor sits, how the overload relay is linked, and how control wires complete the circuit. For technicians, the DOL starter wiring diagram is often the first thing they check before wiring or repairs. Understanding it helps avoid connection mistakes, ensures safe motor operation, and makes troubleshooting faster when issues appear.

Advantages of DOL Starter

In practical use, the advantages of DOL starter become clear very quickly. It is not designed to be fancy or highly technical. It simply starts the motor directly and does that job well. Because of this, many people prefer it for regular motor applications where reliability matters more than advanced control. It works, it lasts, and it does not demand constant attention once installed.

Simple Design

The design of a DOL starter is something most electricians understand almost immediately. The wiring is straightforward and familiar, without confusing logic or extra control layers. Even during installation, things move faster because there is little guesswork involved. If a problem shows up later, tracing the issue is easier, which helps avoid long delays and unnecessary troubleshooting.

Cost-Effective Solution

From a cost point of view, Direct On Line DOL starter makes sense for many users. There are fewer components inside, so the initial price stays reasonable. Over time, maintenance costs also stay low because there is not much that can go wrong. For small factories, workshops, or utility systems, this balance between cost and performance is often the deciding factor.

High Starting Torque

One noticeable thing about a DOL starter is how strongly the motor starts. Since full voltage is applied immediately, the motor develops good torque right from the beginning. This is helpful when the load is heavy or does not move easily at first. Machines reach working speed quickly, which keeps operations smooth and avoids repeated start attempts.

Reliable Performance

When thinking about what is DOL starter advantage, you must know that over long periods, they prove to be dependable. They do not rely on sensitive electronics, so they handle rough conditions better. Once installed properly, they usually keep running without much trouble. Many users trust them simply because they do not create surprises. This steady, predictable performance is why DOL starters are still widely used today.

Disadvantages of DOL Starter

A DOL starter is often chosen because it is simple and easy to use, but it is not perfect for every situation. In many real installations, its limitations become visible after regular operation. The way it starts a motor can affect both the electrical supply and the mechanical parts of the system. Due to this, DOL starters are better suited for specific conditions rather than all motor applications.

High Starting Current

When a motor starts using a Direct Online starter, it pulls a very large amount of current at once. This happens suddenly, without any gradual buildup. In practical settings, this often causes a brief drop in voltage across the supply line. Other machines connected nearby may slow down or flicker. In weaker electrical networks, this high current can even trigger protective trips unexpectedly.

Not Suitable for Large Motors

DOL starters work best with small to medium motors. When used with large motors, the starting current becomes too high to manage safely. This heavy current can heat cables, strain contactors, and overload transformers. Over time, such stress increases maintenance issues and failures. For larger motors, controlled starters are preferred because they reduce startup stress on both the motor and the power system.

Mechanical Stress

A DOL starter forces the motor to jump into motion instantly. There is no soft buildup of speed. This sudden movement creates strong mechanical shock on shafts, gears, belts, and connected machines. If the motor starts and stops frequently, this stress adds up over time. Gradually, it can lead to loosened parts, vibrations, or premature wear of mechanical components.

Limited Control Flexibility

With a Direct On Line DOL starter, the motor either runs at full speed or stays off. There is no option to control how smoothly it starts or how much current it draws. This lack of flexibility becomes a problem in systems that need gentle acceleration or controlled motion. Modern industrial setups often require better precision, which is difficult to achieve using a basic DOL starter.

Why DOL Starter Used in Motor?

Below are the reasons why DOL starter is used in motors.

Simplicity

One reason people still prefer DOL starter use is because nothing about it feels complicated. There are no extra controls to learn or confusing steps to follow. Once it is wired, it simply works. For many everyday motor applications, this straightforward behavior is actually an advantage, especially in places where quick installation and basic operation matter more than advanced features.

Cost-Effectiveness

Cost plays a big role when choosing a motor starter, and that is where DOL starter use makes sense. The design is basic, which keeps both purchase and installation costs low. There are fewer components to replace, and repairs are usually inexpensive. For workshops, small industries, or projects with multiple motors, this saves money without sacrificing dependable performance.

Reliability

Over time, many users trust DOL starters because they rarely give trouble. Once installed correctly, they continue running without constant attention. Their solid construction helps them handle regular electrical loads without frequent breakdowns. This steady behavior is useful in setups where motors run daily and unexpected stoppages could slow down work or cause unnecessary delays.

Ease of Maintenance

Maintenance becomes simpler when the system itself is simple. DOL starters include only essential parts, which makes fault-finding easier. Technicians do not have to spend much time identifying issues. Most problems can be fixed quickly using common spare parts. This reduces downtime and helps keep operations running smoothly without long interruptions.

Also Read: What is an Electric Starter? Types, Uses, and How They Work

Conclusion

It can be stated that DOL motor starters remain one of the simplest, rather inexpensive, and highly effective ways to manage electric motors. It does not matter if people are dealing with single-phase or three-phase motors; they are all the same when it comes to DOL starters. Its advantages include the simplicity of operation, the comparatively low cost compared to the equipment of other manufacturers, and the reliability of the motors produced.

Those looking for DOL motor starters or any other electrical products can visit Lauritz Knudsen Electrical and Automation Smartshop, as our online shop is the best for these devices. We provide a complete line of products that guarantee you to get the most suitable motor starter. Whether you need a basic DOL motor starter or a more professional type, Lauritz Knudsen Electrical and Automation Smartshop offers you all the solutions and services you need to maintain business continuity.

FAQ About DOL Motor starter

Q1. Why is the DOL starter not used for large motors?

Ans. A direct on line starter applies full voltage the moment the motor starts. For large motors, this creates a very high inrush current. The sudden load can stress cables, panels, and transformers. In many plants, this is why the application of DOL starter is limited to small or medium motors rather than heavy industrial machines.

Q2. What are the main components of a DOL starter?

Ans. A DOL starter is built using only the parts that are truly necessary. It usually includes a contactor to switch power, an overload relay for protection, and simple start- stop controls. This basic structure is one reason DOL starter use is common in places where reliability and easy troubleshooting matter more than advanced control.

Q3. Why is an overload relay used in a DOL starter?

Ans. When a motor runs under excess load or faces abnormal conditions, current increases silently. An overload relay senses this rise and disconnects the supply before damage happens. Without it, the motor windings could overheat. This protection is essential in a direct online starter, especially during long operating hours.

Q4. How to choose the right DOL starter for a motor?

Ans. Selecting the right starter depends on the motor’s rated current, voltage, and working conditions. The starter must comfortably handle the starting current without overheating. In practical DOL starter use, matching ratings correctly helps avoid frequent trips and extends motor life, especially in continuous-duty applications.

Q5. Are DOL Starters safe for motor operation?

Ans. DOL starters are considered safe when used within their limits. They include overload protection and reliable switching, which makes everyday operation dependable. However, safety also depends on proper wiring, earthing, and correct sizing. When applied correctly, a direct on line DOL starter performs safely in many routine motor applications.

Q6. How does a DOL Starter work?

Ans. A DOL starter works by connecting the motor directly to the power supply through a contactor. As soon as the start button is pressed, full voltage reaches the motor. The DOL starter working principle is simple but effective, allowing quick startup while the overload relay keeps watch on current flow.

Q7. What is the difference between a DOL starter and Star-Delta starter?

Ans. The main difference lies in how the motor starts. A DOL starter applies full voltage immediately, causing high starting current. A star-delta starter reduces this initial current by changing connections during startup. Due to this, DOL starters suit smaller motors, while star-delta systems handle larger loads better.

Comments